One of the constants of urbanisation, expanding energy infrastructure and increased communications is a high global demand for cables and wires. Consequently, suppliers strive to reduce lead times by streamlining processes. Spooling is one of these key processes, carried out by specialist machines designed to efficiently collect wires and cables in reels.

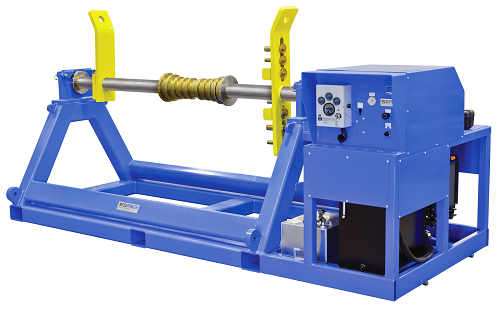

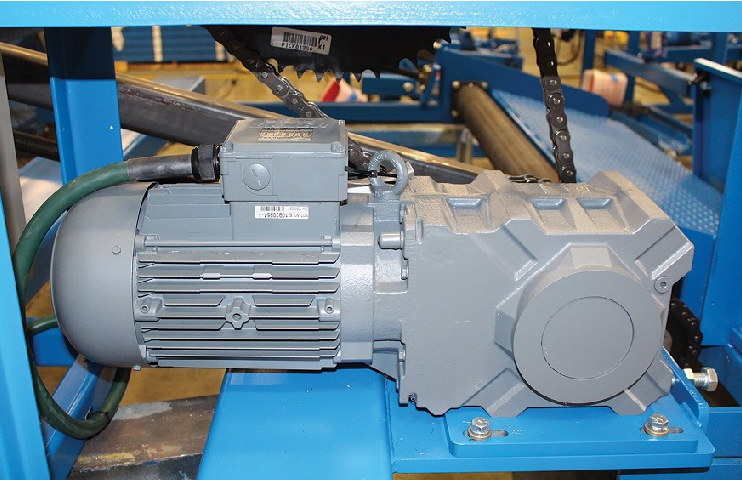

To ensure its latest reel and coiling solution could deliver efficient performance within a compact footprint, Reel Power Industrial selected permanent magnet synchronous geared motors from expert, Bauer Gear Motor, a leading brand of Altra Industrial Motion Corp.

A key segment of the market is copper wire. Utilised in electrical, communications and power infrastructure - demand from contractors across all sectors is high. This pressure is directly transmitted to copper wire suppliers, who desire solutions that spool wire onto smaller reels reliably and efficiently, ready for delivery. Additionally,