We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Search results for: 'speed'

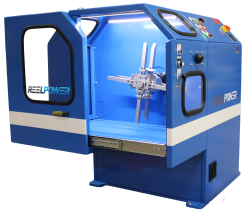

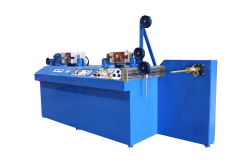

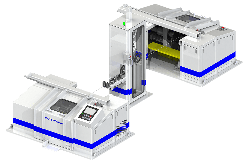

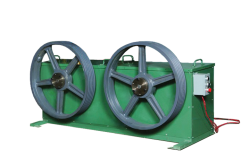

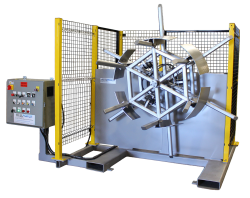

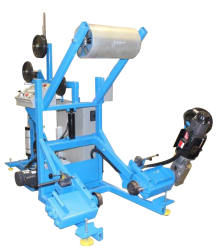

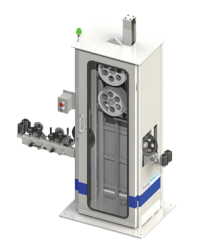

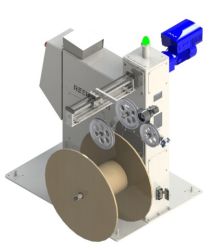

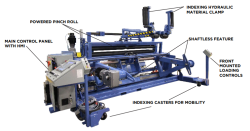

- Standard FeaturesCapacity 24” diameter x 12” wide x 150 LBs Dynamic Braking Feature V-Belt Drive Remote Safety Foot Switch Speed Control Potentiometer IlluminatedThe High Speed Take-ups and Payoffs meet the demand for faster speed, wire and cable manufacturing and rewind. The heavy duty fixed pintle design allows processing speeds up toCustom Pneumatic Powered Expand High-Speed Coiling Machine with custom Coiler 8” x 18.5” x 3.75” wideFull Guarding & Safety Interlocking DoorsLexan Viewing of Operations 2” Capacity Programmable HMI/PLC Measurer Tension Controlled Payoff Dual Take Up With AutomaticFast, Efficient and Economical - PMAC “SAVES ENERGY” OUR NEW RD-10 PMSM - PERMANENT MAGNET SYNCHRONOS AC MOTOR DELIVERS• Smoother acceleration and deceleration - “noReel Drive Take-Up Speed: 0-70 RPM Variable (Standard) Hand Held Pendant Controls Independent Movement Standard1, 2, 3, and 5 HP AC Vector Variable Speed Drive System to maintain line tension and automatically synchronize speed of coiler with speed of process line.$149,532.85Heavy duty floor mounted shaft less take-ups provide you with improved productivity,reducing processing time. Standard Speed Ranges 0-35 RPM or 0-70 RPM. Optional Dual Speed RangeShaftless High Speed Take-Up Re-Spooler/Rewind System Integrated FMP-8 Series Pintle Stule Shaftless Pay-Out and FMT-4 Take-Up Re-spooling/Rewind system.Standard Specifications1 HP SCR Variable Speed Drive, 0-70 RPM Pay-out capacity 20” to 48” dia. x 36” wide x 2,500 lbs. ROM 1700 Measurer - 1/8” to 2” dia.Standard FeaturesHD Frame with Bolt Down Tabs Variable Speed SCR Drive System 10” Dia. UHMW Guide Sheaves Manual Hydraulic Lift JackFor pulling material from Pay-out equipment, or for in-process applications such as extruders. drawing lines, stranding lines, printers and automatic cut-to-length braiders.Wire Insulation Tester WIT 101 High Speed Re-Spooler: The Wire Insulation Tester (WIT ) is powered by a 1 HP variable speed drive system providing speeds up to 1,000 ft perCustom-Designed, Automated Manufacturing Equipment for Processing Flexible Materials Standard FeaturesTakeup - 3 HP A/C Vector Variable Speed Drive Automatic 15mm AmacoilBobbin Spooler & Shaftless Payout is one of the latest and best product with increased speed, it comes with shaftless RSP2 Payoff with advanced tension brake.Re-Reevers is designed for powered take-up,tension controlled payoff,lever operated manual hydraulic,raise & lower, forward & reverse speed and tension controls.Automatic Dual Reel Take Up systems offers high speed material processing and durability for long operational life.ReelPower Industrial Cable new line of Automatic Dual Reel Take-Up systems offers high-speed material processing and durability for long operational life.Insulation Testing and Respooling systems are a completely self-contained unit that was designed/developed for high speed in line production testing on PVC, teflon and other typesThe entire cabling line is PC controlled allowing for individual cable recipe retrieval precisely controlling the cabling bay(s) speeds and Caterpuller Capstan speeds producingThe Twinning & Quadding Equipment consist of on board capstan which pulls the wire at a constant speed to insure the proper lay length, and the tension take-up drive willAutomatic Rewind Coiler comes out with higher coil production at lower cost, greater production flexibility and increase extrusion speed up to 100% and reduce labor cost up toModel HDHSTU & HDHSPO Series of take-ups and pay-offs were developed for higher take-up and pay-off speed applications. A robust and compact design allows for minimum floorSemiautomatic coilers are a low cost alternative to fully automatic equipment. These coilers wind the product as it emerges from the extrusion line automatically followingSemiautomatic coilers are a low cost alternative to fully automatic equipment. These coilers wind the product as it emerges from the extrusion line automatically followingStandard system developed to provide tension controlled pay out and take up operations. Capable of 1,000 lbs of line tension at a 42 inch radius and line speeds of 50 feet perBobbin Spooler System - 3500 FPMNEW DESIGN!Fully automated patent pending split style flooding adjustable coiling head holdsstem pack in place to reduce changeoverUAF and RR machinery custom manufactured to cover your application and specifications • Platform Forklift Base • Model TUAF-30-27 • Speed & torque control/AC vector reelStandard Features• Heavy Duty Entry/Exit Guide Rollers• 4" Wide Belt, Maximum Material 5"• Configurable Line Pull up to 2,000 LBS• Pneumatic Open/Close/Clamp System• 48"• Standard models include dual, multi-grooved capstan wheels and are overed in 24”, 30” and 36”diameter wheel sizes as standard.• Each system is engineered to provide anHD-HSS Hydraulic Automatic Expand/Collapsible (Model- HD-IL-HSS753)3 HP 0-10 RPM 480 3 phase drive, hydraulic assist coiler with speed and tension control Coiler:SINGLE SHAFTED TAKE UP - LOW TENSION APPLICATIONS STANDARD FEATURES INCLUDE:Heavy gauge sheet metal cabinet 3 axis servo drive Spindle maximum weight (50lb) PrecisionINTEGRATED PULLER This tape wrapping system was designed for high speed applications of Mylar, Teflon, Kapton, or metallic tapes for insulating and/or shielding aerospace,Controlled power payoff- Model ILRSPI-005-001 • Custom Material Roller• Centralized Controls• AC Vector Brakemotor STANDARD FEATURES• AC Vector Powered Payoff•Customized Solutions Custom Dancer/Accumulators are manufactured to meet your specifications and applications FEATURES • High Speed Dancer • Large Air Operated Dancer •Standard Features2hp 120v Variable Speed DC Drive Operator Safety Footswitch Structural Steel Frame Bearing Mounted Reel Shaft 2” Diameter Reel Shaft 3” and 4” ArborLow Tension No Contact Dancer The Low Tension No Contact Dancer is designed to protect delicate & sensitive product which may be damaged or over stressed by sheaves in otherDual Shafted Tower Style Take up Model TSTU is a lightweight, economical yet sophisticated take up machine perfect for reeling product up to 1.5 in. width at rates up to 250Single Shafted Tower Style Take up Model TSTU is a lightweight, economical yet sophisticated take up machine perfect for reeling product up to 1.5 in. width at rates up to 250Basket Fillers are the answer in many cases to packing and shipping cable in an inexpensive, reusable container where speed and shipping costs are important. Baskets are alsoAccuracy of +/- 1/2 of 1% at speeds up to 2000 FPM• Capacity range of 1/8” OD minimum x up to 1” OD maximum• Heavy steel plate construction with hardened entrance and exitStationary Shaftless Take-up Machine with external torque control to automatically synchronize speed of take-up with speed of extrusion line, 0-20 FPM for reels or coils 62” toCustom In-Line Dual Take-Up Coiling Machinery FEATURES:Model Shown ILHSS752-002 - Reference 38382 2 HP, 0-5 RPM, 230 VAC, 3 PH. AC Vector Precision Speed & Torque