We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Search results for: 'take-up'

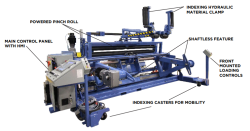

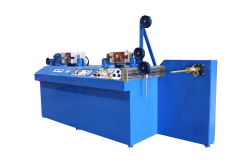

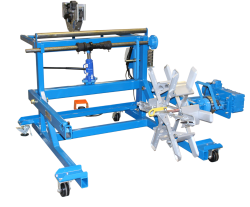

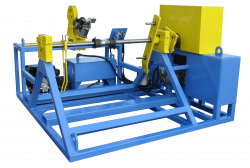

- Fast, Efficient and Economical - PMAC “SAVES ENERGY” OUR NEW RD-10 PMSM - PERMANENT MAGNET SYNCHRONOS AC MOTOR DELIVERS• Smoother acceleration and deceleration - “noReel Drive Take-Up Speed: 0-70 RPM Variable (Standard) Hand Held Pendant Controls Independent Movement StandardHeavy duty floor mounted shaft less take-ups provide you with improved productivity,reducing processing time. Standard Speed Ranges 0-35 RPM or 0-70 RPM. Optional Dual Speed RangeReelpowerwc MRTU Cantilevered Shaft Reeling and Coiling Take Up M/C is well known for its high utility and it comes with hassle free operations, durability and sturdyShafted and Shaftless Machines for Torque Synchronization. Manufactured to your specifications and Needs. Great for Extrusion/Pultrusion Applications.Standard Reel Capacities: TAKE-UPRST3N 30” to 60” dia., 34” wide X 3,000 lbs. RST4N 30” to 60” dia., 36” wide X 4,000 lbs. RST5Automatic Dual Reel Take Up systems offers high speed material processing and durability for long operational life.Traversing Reel Take-ups and Payoffs are some of the most advanced on the market today. The units traverse the entire reel in front of the material line, creating an optimum layerUAF and RR machinery custom manufactured to cover your application and specifications • Platform Forklift Base • Model TUAF-30-27 • Speed & torque control/AC vector reelNK Series: Take-Up Reeling Machine and Coiling Machine comes with powered hydraulic control to raise and lower the reel automaticallyStationary Shaftless Take-up Machine with external torque control to automatically synchronize speed of take-up with speed of extrusion line, 0-20 FPM for reels or coils 62” toDual Spindle ”Low Tension” Take-Up Material is positively pushed onto the spool with our very "low tension” patent pending technology, preventing the profile from crushing.Coiler can be removed to function as a small spool take-up. 8” ID X 12” OD Coils:Accommodates spool/ reel with 1/2” arbor holes 10” wide x 12” OD Comes with quick$183.34Reel Trailers are designed to support and transport a reel of cable to and from the job site with ease and safety.For increased productivity, this machine allows the operator to load or unload finished Take-up reels while unit continues its re-spooling functions. The B-12 is perfect forThe WKT Series Spooling and Coiling equipment is perfect for light to moderate duty applications.Take-ups are standard with a 1 3/8” O.D. shaft with bushings for 2”, 2Shaftless High Speed Take-Up Re-Spooler/Rewind System Integrated FMP-8 Series Pintle Stule Shaftless Pay-Out and FMT-4 Take-Up Re-spooling/Rewind system.FMT60 Shaftless Take-Up and Pay-out Machines Heavy Duty Floor mounted shaftless take-ups provide you with improved productivity, reducing processing time.Wire Insulation Tester WIT 101 High Speed Re-Spooler: The Wire Insulation Tester (WIT ) is powered by a 1 HP variable speed drive system providing speeds up to 1,000 ft perPower sources, such as gasoline or diesel engines, when incorporated in our custom trailer allow you to deliver the trailer to your location. The trailer may then be used as anTraversing Frame Take-Ups and Payoffs are someof the most advanced on the market today, now with capacities up to 250,000 pounds.Traversing Reel Take-ups and Payoffs are some of the most advanced on the market today. The units traverse the entire reel in front of the material line, creating an optimum layerRe-Reevers is designed for powered take-up,tension controlled payoff,lever operated manual hydraulic,raise & lower, forward & reverse speed and tension controls.Pintle Arm (Cantilevered) Shaftless Take-ups and Payoffs are built tough, for years of trouble-free material processing. Standard sizes are available for reels from 28 in. (711mm)The High Speed Take-ups and Payoffs meet the demand for faster speed, wire and cable manufacturing and rewind. The heavy duty fixed pintle design allows processing speeds up toReel changes don't have to mean lost productivity. Now you can run continuous production lines and control your Payouts and Take-ups with horizontal and vertical accumulators fromReelPower Industrial Cable new line of Automatic Dual Reel Take-Up systems offers high-speed material processing and durability for long operational life.The Twinning & Quadding Equipment consist of on board capstan which pulls the wire at a constant speed to insure the proper lay length, and the tension take-up drive willTraversing column style take-ups and payoffs are some of the most advanced on the market today and offer capacities to 80,000 pounds. These units offer unique benefits as trueIn-Line shaftless automatic take-up machinery manufactured to synchronize with your process. It also comes with custom reel capacities designed as per your specification.Traversing Frame Take-Ups and Payoffs are some of the most advanced on the market today, now with capacities up to 100,000 pounds.Traversing Frame Take-Ups and Payoffs are some of the most advanced on the market today, now with capacities up to 100,000 pounds.Model HDHSTU & HDHSPO Series of take-ups and pay-offs were developed for higher take-up and pay-off speed applications. A robust and compact design allows for minimum floorReelpower Industrial RR50 is Ideal for Re-Reeving Cranes, winches and boom-hoist applications that require heavy pay-off tension and take-up rewind capabilities with large, heavy• With 3/4” diameter machine cold roll steel, plug in style-payoff & takeup shafts • Digital stop-to-length 3100 counter with 1/64”-7/8” OD capabilities, dualDesigned to solve “light tension” profile winding challenges Extensive diagnostics make troubleshooting and failure predictions simpler Precision winding patterns,Low Tension No Contact Dancer The Low Tension No Contact Dancer is designed to protect delicate & sensitive product which may be damaged or over stressed by sheaves in otherModel WKT3-014 Mobile Shafted take-up machine for reels 20” to 54” diameter x up to 34” wide. Maximum lifting capacity of 3,000 lbs. and pull from a 2,500 lb. supply reel.$15,590.00Basket Fillers are the answer in many cases to packing and shipping cable in an inexpensive, reusable container where speed and shipping costs are important. Baskets are alsoIdeal For Re-Reeving Cranes, Winches, Boom-Hoist, Steel Reel Applications That Require Heavy Duty Payoff Tension And Take-Up Rewind Capabilities With Large, HeavyCustom In-Line Dual Take-Up Coiling Machinery FEATURES:Model Shown ILHSS752-002 - Reference 38382 2 HP, 0-5 RPM, 230 VAC, 3 PH. AC Vector Precision Speed & Torque