We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Automatic Cut and Transfer Coiling & Spooling Machine ACT-16

The ACT System is highly flexible and reliable applicable to multiple products and applications. Now operating on and offline wire and cable, medical tubing and

plastic profile on applications.

Please enter your email address to receive a verification link.

Didn’t receive the email? Please check your spam folder.

The ACT System is highly flexible and reliable applicableto multiple products and applications. Now operating on and offline wire and cable, medical tubing and

plastic profile on applications.

The ACT System offers a standard, non-proprietary control system adaptable to numerous applications with access by operational and maintenance personnel.

The ACT System touts a robust yet user friendly color interface includes screens for all parameters including performance, operation, maintenance, safety, and

recipe management.

The ACT System offers fast return of investment when replacing manual machines with improved safety and one operator to operate multiple lines.

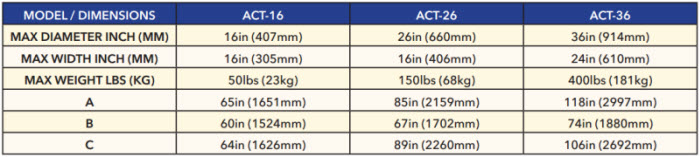

Specifications:

- Higher standard speeds reaching 1000 fpm.

- Clean room ready for medical applications.

- Best available package quality with servo driven indexing turret and material guide arm.

- Precise speed and tension controls with all servo drives.

- Superior safety with a standard “S” guard isolating the operator from the “run” side and optional full guarding with failsafe interlocks.

- Maintenance friendly design with easy access to mechanical and electrical components. System offers far fewer moving parts over the competition.

- Highly reliable with operational longevity and reliability a central focus in the design and testing resulting in lower cost of ownership.

- Greater customer flexibility with non-proprietary control system.

- Convenient mobility with optional pneumatic floor locks allow movement without the use of tools.

- Best in Class package flexibility whether it be spools or coils, through flange or periphery cutting, all can be addressed.

- FDA approved materials used.

Models/Options:

- Auto Coil & Spool Unload

- Auto Packaging (tape, tie, wrap)

- Material Auto Start-up/String-up Assist

- Tension Control & Linear Measurers

- On-Line Printing & Testing